Universal Pack designs and builds cartoning machines for flat blank cartons. We integrate this type of cartoning machine with both our stick pack and sachet packaging machines, according to your needs.

We provide two machines for the flat blanks cartoning unit: one dedicated to the forming process of the cartons, and one dedicated to their closing.

On one hand, our automatic carton forming machines are suitable to erect boxes starting from flat blank cartons by means of mechanical former and hot-melt glue.

On the other hand, our automatic carton closing machines is suitable to close erected boxes by means of tuck and hot-melt glue. Together with carton forming machines, they allow complete secondary packaging provision.

With flat blanks, the sachets insertion takes place between our forming and closing machine, thanks to the top loading system installed at the end of the counting and stacking unit. Moreover, the cartoning machines for flat blanks include some fundamental accessories such as dynamic or static checkweigher, leaflet insertion systems with presence check and tamper evident labeling machine.

Our cartoning machines for flat blank cartons guarantee total flexibility in cartons’ formats. The format of your cartons depends on the number of stick packs and sachets you want to insert. The double balcony allows maximum accessibility to the machine from both front and rear side. In fact, our cartoning machines allow easy access to operators for fast parts and size changeovers.

Our cartoning machines can produce flat blanks cartons with different openings:

FS - Flat blank

FS - Flat blank FS - Casket opening

FS - Casket opening FS - Side opening

FS - Side opening FS - Flip top

FS - Flip top FS - Head opening

FS - Head opening FS - Perforation

FS - Perforation FS - Casket opening + glue closure

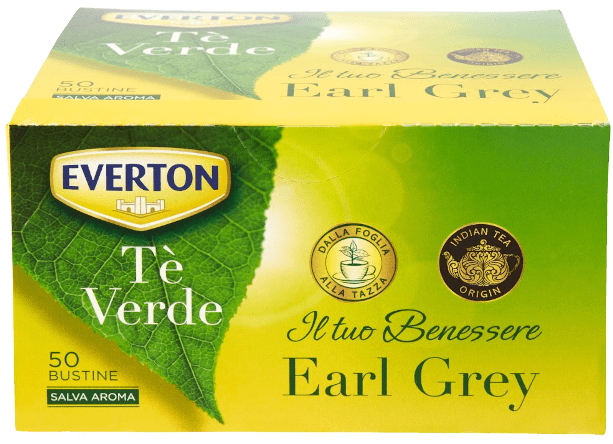

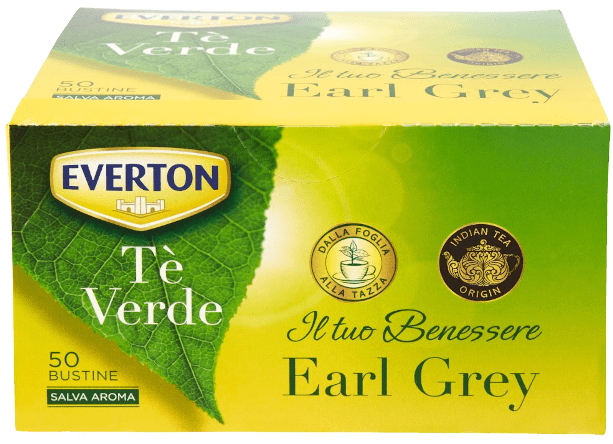

FS - Casket opening + glue closureOur machines for flat blank cartons guarantee total flexibility in cartons’ formats. Your carton format and dimensions vary depending on the number of sachets to be inserted. We can insert only 1 or 2 sachets in smaller cartons (min. 90 x 70 x 35 mm), or even 100 or more sachets in cartons with larger formats (max. 250 x 170 x 120 mm). We have developed patented counting units for any amount of packages to be picked up and inserted into cartons. In recent years, our philosophy is to save as much material and product as possible, both for economic and environmental sustainability.

Our non-stop research in reducing the packaging industry carbon footprint resulted in streamlined machinery design for pocessing recycled, recyclable and compostable laminates. LCA (Life Cycle Assessment) is used to measure the environmental impact of our products and identify optimal ways to reduce it. It is a 360° analysis that goes beyond the mere packaging produced and involves every step of the packaging machinery production process. We develop our solutions shoulder-to-shoulder with the main global film suppliers and test them in agreement with major multinational companies in order to provide them with a turnkey solution able to produce eco-packages.