Consumer division

Pharma division

Close Menu ×

Close Menu ×

Universal Pack designs and builds customized stick pack and sachet packaging machines and cartoning lines for pharma objects. Understanding the needs of our customers is the first step to create and design solutions for their satisfaction in terms of flexibility, reliability and efficiency.

Feeding systems differ because of the nature of the products. Our dosing systems for pharma objects are fully-automatic, semi-automatic or manual. Moreover, we designed dedicated dosing units for specific products such as:

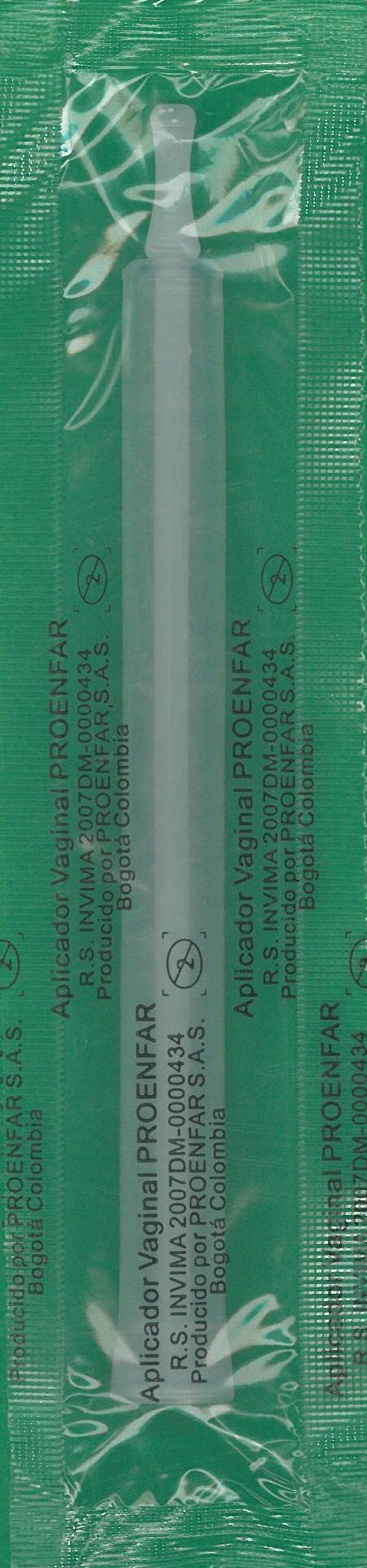

We can provide packaging machines and lines for pharma objects such as blisters, condoms, face masks, monodose vials, pessaries/suppositories, plasters/band aids, pregnancy test sticks, swabs with alcohol, swab tests, vaginal applicators and vials.

As fundamental parts of the safety measures in the pharmaceutical industry, we can provide security systems to govern access and recorded data on the production line. They can manage different levels of access (e.g. operator, factory, administration) making the machinery compliant with CFR 21 part 11 regulation.

The experience we have acquired in our longlasting partnerships with major pharmaceutical corporations helped us develop the most suitable systems in terms of production management, products traceability and compliance with the latest regulations. This process of constant growth and enhancement reflects on our prime quality integrated automatic packaging lines and the abundant set of accessories to increase quality control.

Our internal laboratory analyzes your product and laminate, to design and build the best solution for your need. After several internal tests and a thorough design review, we can manufacture your customized machine.

Our machines and lines are specifically-dedicated to single-dose packages like stick packs and sachets. We can put 1 item in a single pack, whose dimensions vary depending on your marketing goals, nature of the products and production requirements.

In packaging lines for cartoning, our systems allow you to put from 1 up to 100 or more sachets or stick packs in the same carton. We have developed patented counting units for any amount of packages to be picked and put into cartons. In recent years, our philosophy is to save as much material and product as possible, both for economic and environmental sustainability.

Universal Pack seasonings packaging machines can process all typical heat-sealable composite films, for example: PAP-ALU-PE (paper – aluminum – polyethylene), PET-ALU-PE (polyethene terephthalate – aluminium – polyethene) and cold sealable materials. Our machines can also package sustainable laminates such as PP (polypropylene), PLA (polylactic acid), PAP (paper), Bio-PE (bio-based polyethene), and more on request.

Plaster/band aid

Plaster/band aid Swab + alcohol

Swab + alcohol Monodose vial

Monodose vial Vial

Vial Condom

Condom Vaginal applicator

Vaginal applicator Pregnancy test stick

Pregnancy test stick Blister

Blister Pessary/suppository

Pessary/suppository Face mask

Face mask Swab test

Swab test